Colwall Care Home Herefordshire

Project information

Location: Colwall Care Home, Herefordshire

Contractor: Hargan UK

Project Completion: January 2025

Geberit Know-How

Challenge: Hargan UK wanted Geberit to undertake a cost saving analysis to understand the benefits of using Geberit FlowFit compared to a press-fit copper system

Solution: Geberit FlowFit highlighted significant cost savings, particularly around labour costs, so it was an easy decision to switch

Project overview

A purpose-built new-build facility for residential and nursing care, Colwall Care Home from Rotherwood is nestled in the idyllic village of Colwall in Herefordshire, with breathtaking views of the famous Malvern Hills.

The modern care home, which opened in September 2024, includes 60 bedrooms set over three floors with a spa suite, on-site restaurants, a library, craft room and salon. And beyond these benefits for residents the Colwall Care Home project also offers an exemplary demonstration of the value of optimum pipework specification for the developer, contractor and building owner too.

Geberit's own calculations show that using Geberit FlowFit multi-layer press-fit pipes and fittings enabled a huge 37% saving on the total project cost compared with a press-fit copper system, and 34% compared with a conventional multi-layer piping system.

All whilst offering trusted, reliable performance and a host of other benefits, including a significant reduction in pipe diameters.

Why Geberit?

In most cases, multi-layer piping also offers total project cost savings compared with metal systems and the real benefits at Colwall Care Home became evident following a comprehensive cost analysis undertaken by Geberit's project specialists on behalf of HVAC and building services contractor Hargan UK Ltd.

In total, 2,000m of Geberit FlowFit pipework was installed for hot and cold water supply at Colwall Care Home.

Comparing Geberit FlowFit to copper press-fit pipework, the huge 37% reduction in total project cost is almost entirely due to the ease of installation when working with this type of press-fit multi-layer piping system.

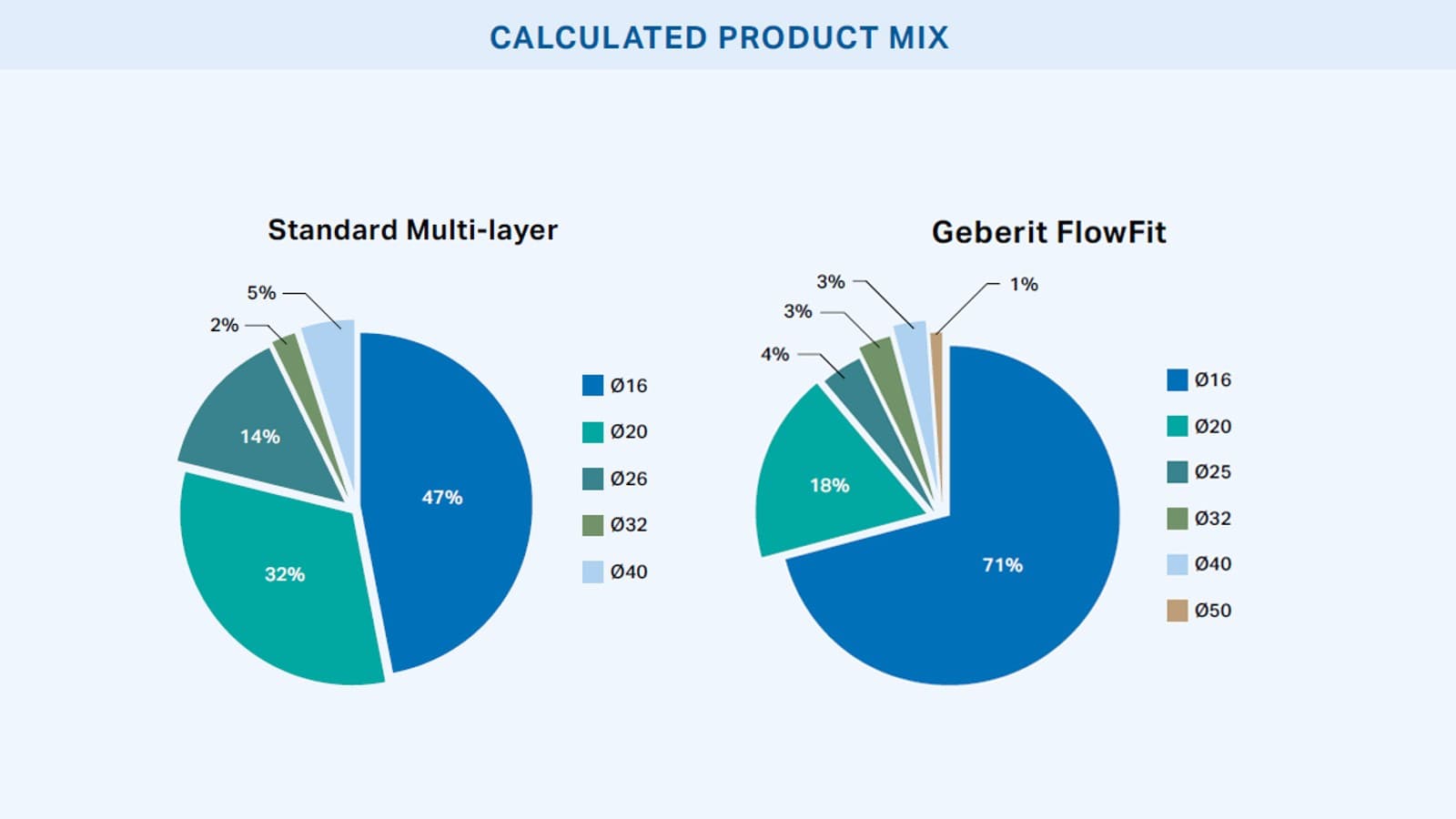

Although generally multi-layer pipes and fittings are more expensive to purchase than copper, the difference is more than made up in labour cost savings. This is largely because 16mm and 20mm pipes (which represented 89% of the total system) can be bent to shape by hand, instead of installing elbows and additional fastening points - which means a cost saving for the customer and leaving the contractor free to move onto their next job quicker.

The cost analysis also showed significant savings when comparing Geberit's FlowFit system to other multi-layer piping systems, particularly due to tooling advancements and a significant reduction in pipe diameters across the flow-optimised system.

Geberit FlowFit fittings come in eight dimensions (of which six were used at Colwall Care Home) and only two pressing jaws are required for the entire range, rather than having to change for each pipe dimension. This saves significant time for installers, as well as needing to undertake less process work when preparing the product.

In addition, the flow-optimised design of Geberit FlowFit - which is the only plastic multi-layer system to include swept geometry in bends - results in minimised pressure losses, closer to that of metal pipework. This means that the water flows through the piping system and to the point of use with less pressure loss, meaning that piping system can be planned and installed with much smaller dimensions.

The total install cost is 37% lower with Geberit FlowFit compared to copper or standard multi-layer.

Delivering the Solution

Mark Firmstone from contractor Hargan UK Ltd, said: “We've used Geberit's Mepla multi-layer system before and we know the benefits of press-fit multi-layer piping systems as a result, but when we saw the potential savings with Geberit FlowFit, it was an easy decision to switch.“

“We knew that we'd be getting a quality product, but the team on site have also said how much easier it is to install, even compared to Mepla. Being able to use one set of jaws makes a big difference when we're fitting in tight spaces.“