Industrial pipes for industrial applications & shipbuilding

A multifaceted system for challenging tasks

Plumbers and sanitary engineers are often confronted with complex questions in the course of planning industrial pipelines. Whether the issue is critical media, operating parameters or standards and regulations that need to be taken into account, all these considerations need a high level of knowledge and expertise.

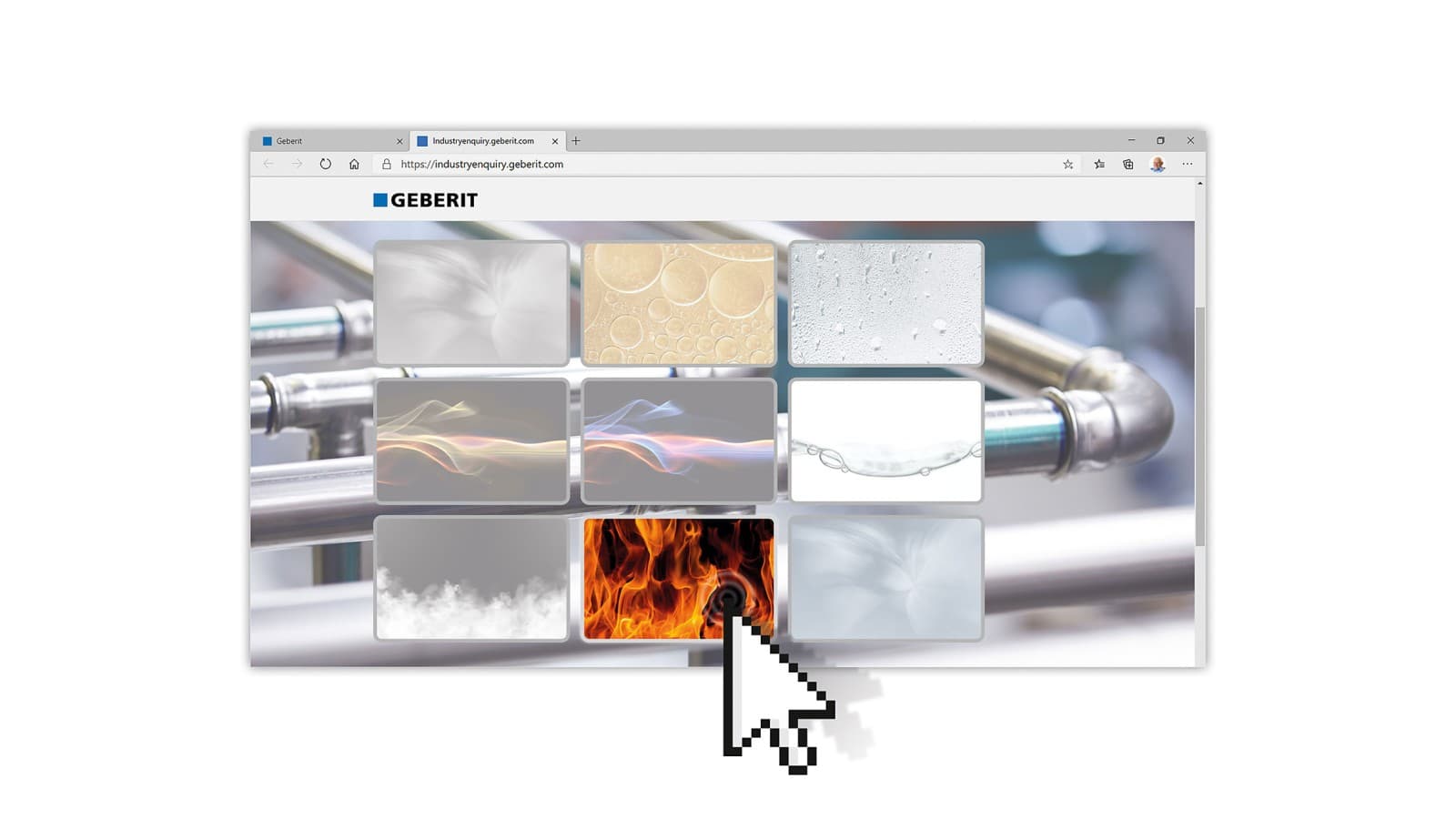

Geberit Industrial Application Tool

Industrial gas, compressed air, treated water, oil, cooling lubricant and more. Which piping system can be used for different operating parameters? The Geberit Industrial Application Tool supports users in selecting a suitable piping system.

Geberit Competence Centre for Industry (CCI) Support for industrial piping systems

The project managers and engineers at the CCI are available to help with questions on project planning and on the use of Geberit piping systems in industry and shipbuilding.

Services:

- Coordination of national/international industry and shipbuilding projects

- Advice on application engineering

- Technical support with Geberit piping systems during planning

- Training and education

Contact details:

Monday to Thursday 8 a.m. to 5 p.m.

Friday 8 a.m. to 1 p.m.

Phone number: +49 (0)2173 285 310

Email: industry.cci@geberit.com

Industrial applications

Chemicals and pharmaceuticals

Process water, cooling water and demineralised water, compressed air, industrial gases, fire extinguishing systems

Mechanical engineering

Process water, cooling water and demineralised water, compressed air, industrial gases, technical liquids, fire extinguishing systems

Foodstuffs industry

Drinking water pipes, saturated steam, industrial gases, cleaning agents/disinfectants

Automotive industry

Process water, cooling water and demineralised water, compressed air, industrial gases, technical liquids, oils and motor fuels

Shipbuilding

Drinking water pipes, heating/cooling, machine room systems, seawater pipes, fire extinguishing systems

Geberit product highlights for industrial and shipbuilding applications

Aggressive media, low temperatures and high pressure levels are just some of the challenges that confront sanitary engineers who are dealing with pipelines for industry. Not only that, but in most cases they are also required to adhere to special safety precautions and strict approval procedures, as well as cope with time pressure and possess excellent know-how.

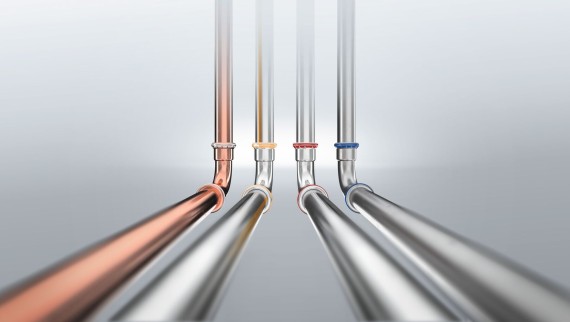

Piping systems for many media and applications

Geberit offers a comprehensive range for industrial customers:

- Reliable piping systems for supply and disposal

- Decades of experience and expert advice for industrial applications

- Fast and safe connection technology

- All the relevant approvals

- BIM data for Autodesk® Revit®

Selected media

- Operating, cooling and treated waters

- Extinguishing water

- Salt water

- Technical liquids

- Fuels and oils

- Saturated steam

- Compressed air

- Inert and industrial gases

Industrial applications with Geberit

Automotive

The modern automotive production and components industry requires a large range of clean, safe and flexible piping systems; from process lines to transporting liquid and gas materials, to filling the vehicles with operating liquids or for supply of the production robots, machines and plant. Construction processes in the automotive industry are already highly optimised, but the modern and flexible production can be enhanced by the innovative connection technologies of Geberit Mapress and Geberit Mepla press connection systems.

- Geberit Mapress and Geberit Mepla - two supply systems for all applications

- Suitable for numerous process lines in automobile production

- Silicone-free pipes and fittings (Geberit Mapress), free from substances that constrain from painting

- Highly cost effective in plant through reduction of down time

- Cost reduction through fast, clean and flexible assembly

- Cold pressed, safe connections without threading, soldering, brazing or welding

CLEANER, MORE FLEXIBLE PIPING SYSTEMS FOR VEHICLE PRODUCTION

The breadth of supply systems required in the automotive industry ranges from water supply, process water and chilled water for welding robots to filling lines for operating liquids in the new vehicles produced such as fuel, brake fluid, screen wash or antifreeze. Automotive producers and deliverers also need piping systems for compressed air supply for work and control air as well as for fire protection systems. For all the challenges in automotive production, Geberit offers safer, cleaner and more flexibly installed solutions with its multi-faceted press systems - Geberit Mapress and Geberit Mepla. Compared to welding, Geberit press connection systems clearly reduce the down time of the equipment during installation and maintenance and does not require hot works.

INTERNATIONAL STANDARDS AND APPROVALS FOR A WIDE SPECTRUM OF GEBERIT MAPRESS

Geberit Mapress press fittings and system pipes are available in the silicone free materials stainless steel and carbon steel. Geberit Mapress is suitable for all materials in the process lines within the automotive industry. The press connection system can be installed without causing a fire risk, because hot work is not required.

Food and Beverage

In hygienically sensitive areas of the food industries many different process lines are required. The innovative Geberit Mapress stainless steel press connection system fulfils the strict hygienic challenges of food industries for a variety of applications. In addition, Geberit Mapress stainless steel supply systems can be disinfected chemically or thermally.

- Hygienic harmless materials fulfil the hygienic challenges of the food industry

- Geberit system pipes and press fittings are individually capped

- Clean installation technology through cold presses without soft solder, hard solder or welding

- Geberit Mapress Stainless Steel supply systems can be easily disinfected chemically or thermally

- The high molybdenum content of Geberit Mapress Stainless

MEETING STRINGENT HYGIENE REQUIREMENTS

Geberit Stainless Steel press connection systems fulfil the strict hygiene requirements for the process lines for the production of food and beverages. Geberit Mapress and Geberit Mepla guarantee a safe and clean installation. Whether in breweries, cheese dairies and creamaries, sugar factories or abattoirs , Geberit’s solutions are ideal for process lines for cleaning & disinfecting products, saturated steam for disinfection & sterilisation and for various packaging methods including vacuum and gases including technical gases like hydrogen, nitrogen and oxygen.

GEBERIT MAPRESS STAINLESS STEEL FOR CLEANING AND DISINFECTION MATERIALS

Geberit Mapress press fittings and system pipe are used in the pharmaceutical and food industry in corrosion resistant stainless steel only. Four different seal rings and international approvals offer a wide spectrum of use of the Geberit Mapress system for process lines for cleaning and disinfection products or for saturated steam. The clean installation technology takes into account the required installation hygiene, as stainless steel does not influence the purity of the gases used. All supply systems lines can be chemically or thermally disinfected.

GEBERIT MEPLA IN THE FOOD INDUSTRIES

The multilayer pipe system Geberit Mepla can be used in the food industries for compressed air, potable water installations and for heating. Geberit Mepla lends itself to safe, clean and flexible installation. All Geberit Mepla fittings and system pipes are closed with caps and delivered individually packed. This way, the noted hygiene in installation is maintained. Also, installation times are clearly reduced through reduction of down time which is highly cost effective in plant.

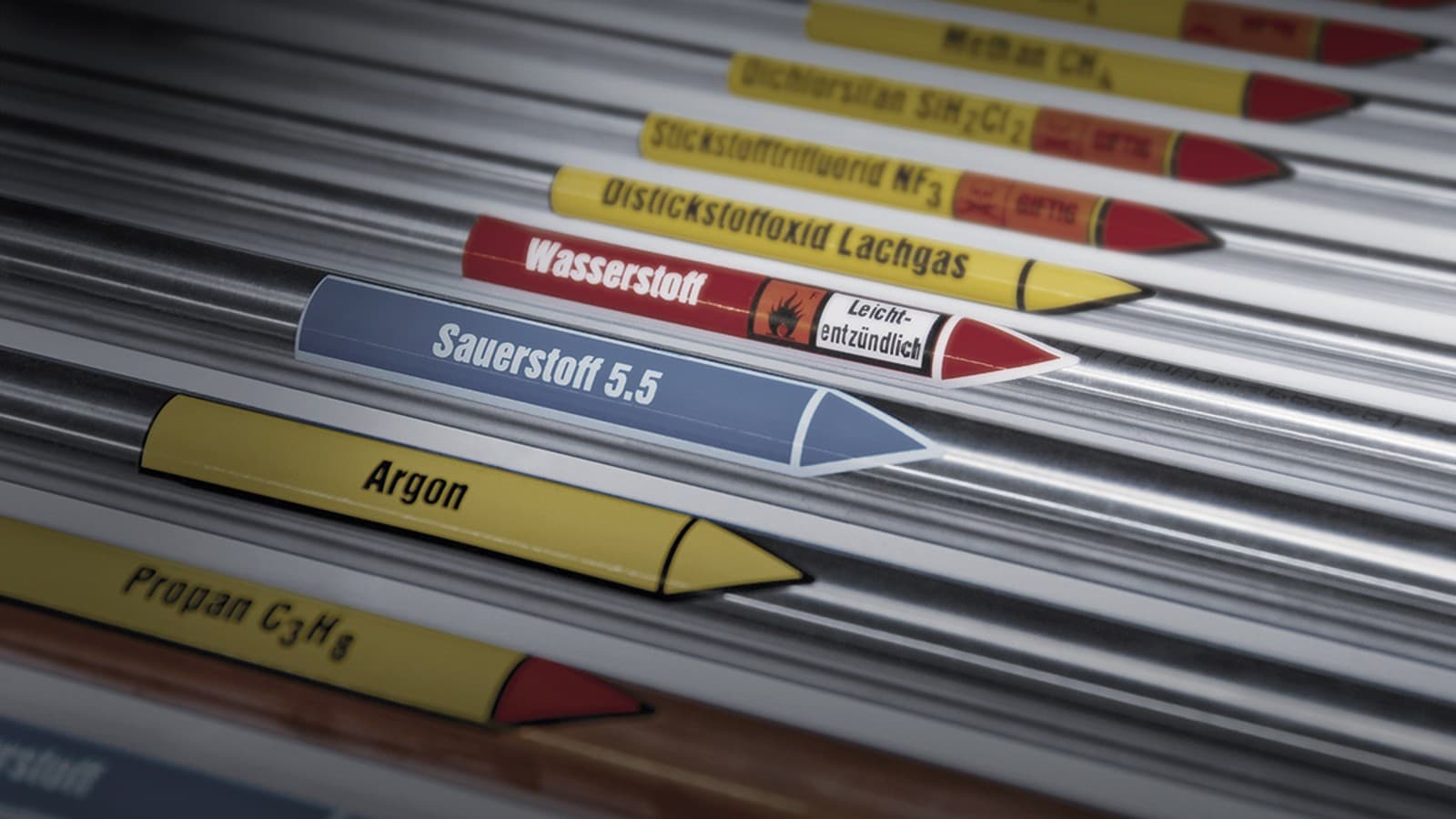

Plant and Machinery

In the plant and machinery industry tight, stable pipe connections are required for various special media, for example mineral oils and motor fuels, compressed air, fuel gases, inert gases and special technical gases like oxygen. In combined heat and power plants, steelworks or paper factories, Geberit supply systems can be used for operating and chilled water, purified water, process water, saturated steam and condensate lines, and also sprinkler and fire extinguishing systems.

- Geberit Mapress is TÜV approved and suitable for special media and gases like oxygen, hydrogen and acetylene

- Geberit Mapress is capable of handling over 200 chemicals

- Cost reduction through fast, clean and flexible installation

- High plant availability through reduction of down time

- Extensive fitting range in various materials

- Clean cold pressing system without fire risk, also ideal for repairs and extensions

STABLE, VARIED AND SECURE SOLUTIONS FOR INDUSTRY

The wide range of plant and machinery industries need supply systems for the supply of cooling substances, operating and chilled water, condensate lines, from compressed air control, lubricants and oil to inert gases and technical gases. Further piping systems for compressed air delivery or for breathable air as well as for sprinkler systems, fire extinguishing lines or hydrants are also required. For these challenges in the manufacturing industry, Geberit Mapress and Geberit Mepla press fitting systems offer fast, safe and clean solutions. Through the flexible use, down time in the plant and machinery industry can be clearly reduced.

GEBERIT MAPRESS IS TÜV APPROVED AND ALLOWED FOR MANY MEDIA, INCLUDING OXYGEN AND HYDROGEN

The Geberit Mapress press connection system offers an extensive fitting range in the materials stainless steel and unalloyed carbon steel. Different seal rings, TÜV approved, made to international standards and conformities widen the spectrum of use of Geberit Mapress Stainless Steel to over 200 chemicals and special media. Geberit Mapress is installed easily and economically, with no danger and without open flames. Where previously welding was used, today clean and long lasting safe pipelines can be installed with Geberit press connection systems in the shortest time.

GEBERIT MEPLA - FLEXIBLE IN MANY INDUSTRIAL APPLICATIONS

Geberit Mepla is also suitable in the process industry for an easy and fast installation technology. The multilayer pipe system can be used for compressed air, cooling systems or for clean and safe hot and cold water installations and heating.

Chemical and Pharmaceutical

Stable, reliable pipe connections are essential in chemical and pharmaceutical production. Geberit supply systems can be used to transport chilled water, processed water & process water as well as condensate lines, sprinkler and fire extinguisher systems or hydrants, mineral oils & fuels, compressed air, fuel gases, inert gases and technical gases. Geberit Mapress press connection system is also suitable for the supply of chemicals, as long as Geberit’s approval is given. For safe waste disposal Geberit HDPE provides the perfect drainage solution for the chemical and pharmaceutical industry.

- Reduction of the installation time through fast, clean and flexible installation

- High plant availability due to the minimisation of downtime

- Corrosion resistant materials like Mapress Stainless Steel

- Industry-safe connection technology through factory made fittings programme

- Geberit Mapress is TÜV approved und allowed for over 200 chemicals

- Safe working in hazardous areas, due to cold pressed safe connections

VERSATILE PRESS CONNECTION SYSTEMS FOR THE SUPPLY OF CHEMICALS

Required in the modern chemical industry there are a great breadth of applications for press connection systems in supply and drainage. There are coolants, compressed gases, chilled and heated water, potable water, lubricants and oil as well as fire protection systems. Further pipelines for the supply of compressed air, for technical gases and for process, deionised and chilled water are required. For all these challenges in the chemical industry Geberit offers the versatile press connection systems Geberit Mapress and Geberit Mepla which provide flexible, clean and secure solutions. Where previously welding was used, today clean and long lasting safe pipelines can be installed with Geberit press connection systems in the shortest time. The reduction of installation times provides for a clearly higher plant availability.

GEBERIT MAPRESS – APPROVED FOR USE WITH MORE THAN 200 CHEMICALS

With the press connection system Geberit Mapress, the corrosion resistant materials stainless steel and unalloyed carbon steel is suitable for a multitude of approved and permitted media. Various seal rings, TÜV release, international approvals and certificates of conformity offer a wide spectrum of usage of the Geberit Mapress system, ranging from waters, compressed air, oils and fuels, through to inert and technical gases, to over 200 chemicals. Because the Geberit press connection system works without soldering and welding, it can be safely installed in potentially explosive areas.

GEBERIT MEPLA IS USABLE ALL-ROUND IN THE CHEMICAL INDUSTRY

The multilayer press system Geberit Mepla can be used in the chemical industry for compressed air, cooling systems or for the classic hot and cold water installations and heating.

Shipbuilding

From private yachts or passenger vessels to offshore projects, Geberit offers many solutions for supplying and draining off various medias in shipbuilding. The Geberit advantage for shipbuilders is thin-walled system pipes of metal or plastic that can be pressed into a system to significantly reduce the overall weight. A variety of media, including fresh water, seawater, compressed air, fuels and oils can be transported through our systems.

- Internationally recognised approvals from shipping and military authorities

- A piping system for various applications in shipbuilding with a comprehensive range of different materials

- Geberit Mapress pipe systems and fittings can save up to 50 percent in weight compared to similar materials

- Cost reduction through easy and quick installation technique

- No fire hazard, as cold pressing system and processing without open flame

- Suitable for new build and renovation, without fire hazard from welding and brazing

GEBERIT PRESS FITTING SYSTEMS HAVE CIVILIAN AND MILITARY APPROVALS

Typical operational areas for reliable, long life pipes within shipbuilding are potable water installations, fire protection systems, engine room systems with pipes for water emulsions/oil emulsions, mineral oils and lubricating oils, heating and cooling systems with refrigerant and antifreeze as well as compressed air and inert gases. A variety of media can be distributed within Geberit piping systems for shipbuilding, including cooling water, process water, demineralised water as well as sea water and bilge water. The Geberit Mapress materials of stainless steel, carbon steel, copper and a sea water resistant copper-nickel-iron-alloy (CuNiFe) satisfy the requirements of the marine industry and have acquired international civilian and military authorisations from the most important shipping authorities.

THE GEBERIT MEPLA METAL COMPOSITE PIPE SYSTEM FOR HOT AND COLD DRINKING WATER

In using Geberit Mepla press fitting pipes and fittings in shipbuilding, large weight savings can be achieved. Geberit Mepla is a lighter material which is a huge advantage within the shipbuilding industry.

GEBERIT MAPRESS CUNIFE - FOR THE SEA WATER COOLING AND SPRINKLER SYSTEMS

Geberit Mapress CuNiFe is a salt water-resistant copper-nickel-iron alloy (CuNi10Fe1, 6Mn) and has proven itself over many years within shipbuilding, for pipelines carrying salt water. It eliminates the need for welding meaning no fire hazard and effectively prevents corrosion. The Geberit Mapress system is used in shipbuilding for engine room systems, the supply of service water, pool water and heating water. Geberit Mapress CuNiFe is, up to a chloride content of 30 g/l, sea water resistant and approved for sea water cooling supply and is also certified for sea water-powered sprinkler systems

Energy

Geberit Mapress in stainless steel and carbon steel is suitable for transporting fuels and oils. Our pressing systems have been in use in fuel and oil supply pipes for over 15 years, particularly in power plants, workshops and in petrol stations. The permanently high tightness of the connection and its quick and simple installation technology mean that Geberit Mapress is a state-of-the-art, high-quality and economical connection technology.

- Highly cost effective in plant through reduction of down time

- Corrosion resitant materials like Geberit Mapress Stainless Steel

- No fire hazard, as no hot works are required to install the system

- Clean, safe connections without threading, soldering, brazing or welding

- Ability to be used on a variety of different fuels and oils

- Geberit Mapress is TÜV approved and allowed for over 200 chemicals

Geberit Mapress Stainless Steel

System pipes and press fittings made of high-alloy, austenitic, stainless CrNiMo steel with material number 1.4401 in accordance with BS EN 10088, with dimensions d12-108 with TÜV component ID TÜV.A.271-07.

Geberit Mapress Carbon Steel

Press fittings made of non-alloy carbon steel E195 with material number 1.0034 in accordance with BS EN 10305, outside zinc-plated, in conjunction with system pipe made of non-alloy carbon steel E195 with material number 1.0034 in accordance with BS EN 10305, outside zinc-plated with dimensions d12-108 or polypropylene (PP) unjacketed with dimensions d12-54 in accordance with BS EN 10305 with TÜV component ID TÜV.A.271-07.